In Engine Design and Power Generation

The APEX PowerTrain is an integrated hybrid-electric propulsion system with an on-board clean burning power plant.

This power plant is an ultra-low emissions and highly fuel efficient Stirling Cycle engine. Instead of producing electricity from a power plant, electricity is generated on board the vehicle via Stirling engine. The APEX series hybrid, superior to all conventional and electric vehicles, consists of the integration of dynamic braking, ultra-capacitors, lithium ion batteries, a thermopile array and solid state electrical system.

With the advent of our patented APEX hybrid technology, it is now possible to replace the internal combustion engine with the far superior Stirling Cycle engine. Fuel efficiency is significantly increased, harmful emissions are dramatically cut, and the system can utilize either the global fueling infrastructure already in place or alternative bio-fuel sources.

The Stirling Cycle engine yields more than twice the fuel efficiency of an internal combustion engine.

The Stirling Cycle engine yields more than twice the fuel efficiency of an internal combustion engine.

The APEX system is made possible by our 7 integrated Technology Modules

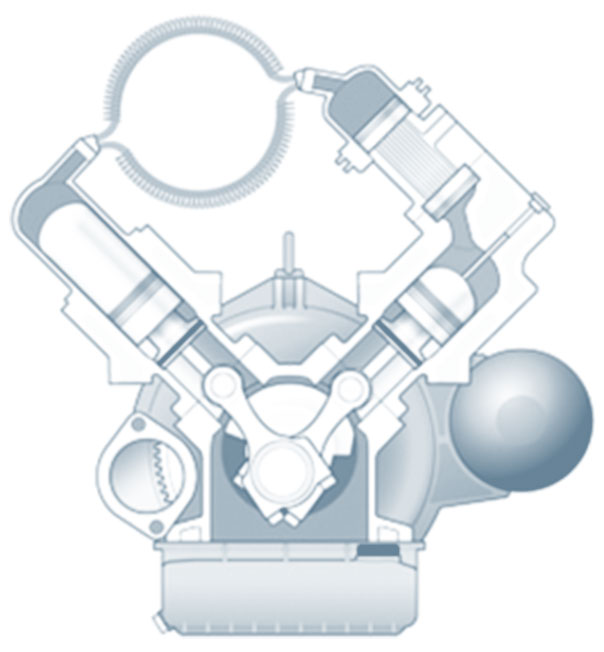

Our Automotive Stirling Cycle engine design was improved by NASA and perfected by Quantum with 50% fewer moving parts and superior torque to the internal combustion engine. The engine design is scalable to higher power ratings. The Stirling is an external combustion engine which means it burns the fuel/air mixture at atmospheric pressure eliminating 90% of the oxides of nitrogen (NOx) commonly produced by internal combustion engines.

Permanent magnet generators (no coils) operated at high engine rpm allows for a smaller, lighter, more powerful generator with high power output, providing superior torque.

Ultra-caps reduce required batteries by 60%, provide for rapid acceleration and enable rapid charging. This reduces fire risk and increases the usable life of the battery system. Ultra-caps have 90% charging efficiency, 1 billion lifetime charge cycles, and superior tolerance for extreme temperatures. Our dynamic breaking has a 90% braking energy recapture, made possible by the Ultra-caps.

The combination of the ultra-caps and the Li ion batteries reduces the size and weight of the electrical storage system to a size significantly smaller compared to EV’s. Longer life, lower fire risk due to reduced charge cycles and eliminated “fast charge” requirements of EV systems. Easily replaced at much lower cost than an EV. The buffering provided by the Ultra-Caps extends battery life by more than 50%.

Thermoelectric Heat Energy Recovery Module (THERMO) is patented system for energy recovery from exhaust gases using advanced thermopile technology on the exhaust system. This is accomplished by employing the Seebeck effect by using dissimilar metals to generate an electrical current. The THERMO has no moving parts and improves overall efficiency of the APEX PowerTrain.

The wheel motors are electrically powered when the driver accelerates the vehicle. When braking, we convert the energy to electricity through dynamic braking by using the wheel motors as generators to recover 90% of the braking energy.

Quantum’s patented system control algorithm integrates our seven TechMods through the IGBT. The IGBT controls the flow of electrical current to and from the various components of the vehicle.